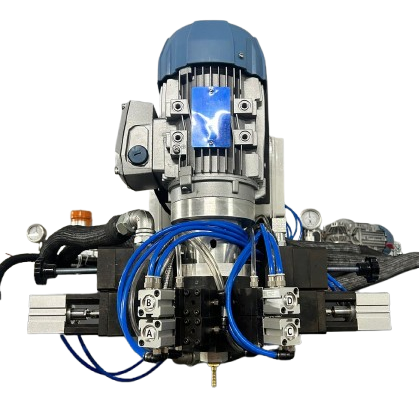

Trident(Three Component)

- We build customized TRIDENT machines for advanced cast polyurethane (PU) production.

The TRIDENT model is designed with modularity and adaptability at its core, enabling you to configure the machine to match your exact production needs, material characteristics, and output targets. Whether you require a compact unit for limited space or a robust setup for high-volume industrial output, the TRIDENT system offers unmatched flexibility.

Engineered for efficiency and precision, the TRIDENT machine features a fully industrialized design that is both durable and scalable, ensuring reliable performance even under demanding conditions. Its architecture supports a wide range of casting techniques, providing a seamless experience from setup to final product.

With the TRIDENT model, you’re not just investing in equipment—you’re choosing a future-ready, intelligent solution that evolves with your polyurethane casting process.

Trident Model Configuration

The TRIDENT series from ABVS Tradelink is engineered to offer modular, scalable, and high-performance solutions for cast polyurethane (PU) applications. The lineup, ranging from B10105 to B202010MC, supports various production volumes with tank capacities of 100 kg to 200 kg, and includes multi-tank setups (e.g., 100/100/50 or 200/200/100 kg) to meet diverse casting needs.

Designed for maximum flexibility and customization, the TRIDENT machines can be configured with single-color, dual-color, or multi-color units (up to 4). This makes them ideal for manufacturers seeking high-volume output, color variation, and efficient, continuous production.

Models such as the B10105MC, B20107MC, and B202010MC offer 2 TO 4 color units, making them perfect for complex production environments where color variation and batch control are essential. With the TRIDENT series, you're investing in a future-ready polyurethane casting system built to evolve with your production goals.

| Model No | Tank Size (KG) | Color Unit |

|---|---|---|

| B10105 | 100, 100, 50 | 0 |

| B10105C | 100, 100, 50 | 1 |

| B10105MC | 100, 100, 50 | 2 TO 4 |

| B20107 | 200, 100, 70 | 0 |

| B20107C | 200, 100, 70 | 1 |

| B20107MC | 200, 100, 70 | 2 TO 4 |

| B202010C | 200, 200, 100 | 1 |

| B202010MC | 200, 200, 100 | 2 TO 4 |

Product Features

- Tank Capacities: Choose from models offering 50, 70, 100 or 200 kg tanks to match your batch size and workflow.

- Color Units: Available in 0, 1, or 2 to 4 color configurations—perfect for custom PU molding.

- Consistent Mixing: High-precision mixing ensures optimal material properties and minimal waste.

- Scalable Design: Easily expand or upgrade your production setup as business demands grow.

- User-Friendly Interface: Intuitive control systems and HMI for seamless operation.

- User friendly human machine interface(HMI)

As mechanical and electrical design, automation and software. This full integration enables us to continuously build our own expertise and to provide the customer with long-term support. machines feature a highly perfected digital interface to ensure an easier handling of the machine. This Human Machine Interface enables a dynamic, intuitive and an interactive asset for operators. As well as the common features, our HMI offers to select easily several languages.

- Quick link toolto easily and efficiently go to screen menus

- Predictive preventive maintainance operation

- Production data recording withpouring reports

- Our machines are build forthe process of casting polyurethane in all thinks of casting techniques

- Open module

- Continuous casting

- Short by weight

- Rotational casting

- The proven technology of machines enable themto process many kinds of reactive system

- Hot cast polyurethane elastomers

- Cold cast polyurethane elastomers

- PU formulations for tpubased products csn be successfully processed

- And other thermoset materials

- The necessary items for a pericular purpose design to operate your production, whatever the casting techniques

Material recirculation unit for each component. Combined with the electrical heating system, uniform temperature and an even viscosity of the products. The recirculation ensures the right pump speed from the beginning of the casting reducing prepouring time and material loss. In-house engineering makes machines the most efficient works for the successful production of cast polyurethane parts. This expertise drove us to identify and optimize the core characteristics of our machines.